Use VCE Exam Simulator to open VCE files

Get 100% Latest Microsoft Certified: Dynamics 365 Supply Chain Management Manufacturing Functional Consultant Associate Practice Tests Questions, Accurate & Verified Answers!

30 Days Free Updates, Instant Download!

Microsoft Certified: Dynamics 365 Supply Chain Management Manufacturing Functional Consultant Associate Certification Practice Test Questions, Microsoft Certified: Dynamics 365 Supply Chain Management Manufacturing Functional Consultant Associate Exam Dumps

ExamSnap provides Microsoft Certified: Dynamics 365 Supply Chain Management Manufacturing Functional Consultant Associate Certification Practice Test Questions and Answers, Video Training Course, Study Guide and 100% Latest Exam Dumps to help you Pass. The Microsoft Certified: Dynamics 365 Supply Chain Management Manufacturing Functional Consultant Associate Certification Exam Dumps & Practice Test Questions in the VCE format are verified by IT Trainers who have more than 15 year experience in their field. Additional materials include study guide and video training course designed by the ExamSnap experts. So if you want trusted Microsoft Certified: Dynamics 365 Supply Chain Management Manufacturing Functional Consultant Associate Exam Dumps & Practice Test Questions, then you have come to the right place Read More.

Featured Certification of Dynamics 365 Supply Chain Management Manufacturing Functional Consultant: The Transformation of Manufacturing in the Digital Era

Manufacturing has transcended the age-old perception of repetitive mechanical labor confined to isolated factory floors. Today, it embodies a fusion of precision and predictive intelligence, where agility is not merely a corporate mantra but a necessity for survival. The forces driving this evolution are multifaceted, ranging from globalization and intensifying consumer expectations to the relentless pursuit of operational excellence. The modern industrial ecosystem is shaped as much by data as it is by human endeavor, and those who navigate it successfully must balance technical mastery with strategic foresight.

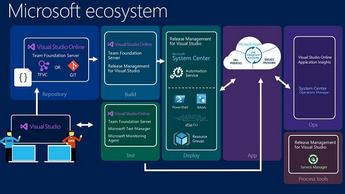

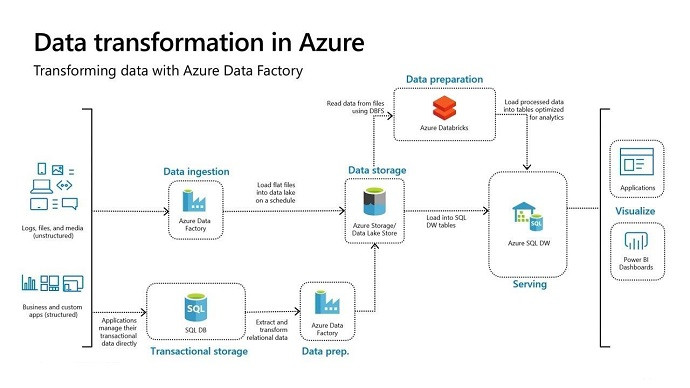

At the heart of this metamorphosis lies digital intelligence. Cloud platforms provide seamless connectivity across the supply chain, enabling stakeholders to access real-time information, monitor production metrics, and collaborate with unprecedented speed. Artificial intelligence has become an indispensable tool for forecasting demand, predicting equipment maintenance, and optimizing inventory levels. Interconnected systems facilitate a level of visibility and control that transforms linear production sequences into dynamic, data-driven workflows. The once predictable rhythm of the assembly line has evolved into a complex, responsive ecosystem where every decision echoes throughout the entire operational framework.

As enterprises adopt these advanced technologies, the role of the modern professional has shifted dramatically. Success in this environment requires more than familiarity with software; it demands an intricate understanding of production realities, supply chain intricacies, and human workflows. Professionals must anticipate challenges, interpret the nuances of complex operations, and translate digital possibilities into actionable strategies. They are no longer implementers of technology but orchestrators of systemic transformation.

The Microsoft Dynamics 365 Supply Chain Management, Manufacturing Functional Consultant represents the embodiment of this new archetype. This professional is tasked with more than configuring software modules; they interpret business imperatives, integrate technological capabilities with operational objectives, and align system functionalities with strategic priorities. In essence, they bridge the chasm between machine logic and human operations, ensuring that technological solutions are not only efficient but also comprehensible and actionable for diverse stakeholders.

The transformation of manufacturing necessitates individuals who can act as translators between disparate domains. They must navigate the technical intricacies of ERP platforms, understand the ebb and flow of production cycles, and communicate effectively with operators, managers, and executives alike. Their work transcends configuration tasks; it encompasses process optimization, workflow redesign, and strategic alignment. In a landscape defined by complexity and rapid change, their presence ensures that technology serves human needs rather than dictating them.

Manufacturing enterprises have recognized that isolated systems and reactive problem-solving are no longer viable. The contemporary industrial environment demands integrated platforms capable of providing instantaneous insights, predictive analytics, and operational agility. Functional consultants are central to this paradigm shift. They do not merely implement technology; they embed intelligence into the operational fabric of the enterprise, creating systems that are adaptive, resilient, and human-centered.

The interplay between technology and operations has become increasingly intricate. Modern production ecosystems are a tapestry of machines, sensors, data streams, and human expertise. Each element influences the others, and understanding these interactions is crucial for achieving efficiency and operational excellence. Consultants equipped with deep knowledge of Dynamics 365 are uniquely positioned to navigate these complexities, aligning digital configurations with the practical realities of manufacturing.

For instance, resource scheduling in a discrete manufacturing environment requires a keen awareness of equipment capacity, labor availability, and material constraints. An incorrect configuration can trigger bottlenecks, delays, and cost overruns. Similarly, in process manufacturing, the management of raw materials, batch production, and quality control demands both technical precision and an understanding of human workflows. Consultants must design systems that accommodate variability, anticipate potential disruptions, and maintain continuity in production.

Moreover, the adoption of cloud-based solutions has introduced new possibilities for operational oversight. Real-time monitoring of production lines, predictive maintenance alerts, and automated quality checks provide managers with actionable intelligence. Yet, without professionals who can translate these digital signals into operational decisions, the potential of these systems remains unrealized. The consultant’s role is to ensure that technological advancements enhance human judgment rather than replace it.

While technology drives efficiency, the human dimension of manufacturing remains paramount. Employees on the shop floor, supervisors managing daily operations, and executives steering strategic direction all require systems that are intuitive, reliable, and aligned with their objectives. Functional consultants serve as the conduit between these diverse groups, facilitating communication, promoting understanding, and fostering trust in digital tools.

Training and adoption are critical components of this process. The introduction of new systems can be disorienting, particularly for operators accustomed to legacy workflows or manual processes. Consultants guide stakeholders through this transition, offering hands-on support, conducting workshops, and providing contextual explanations that demystify technical configurations. Their work ensures that systems are not perceived as intrusive mandates but as enablers of productivity and efficiency.

Furthermore, consultants bring an ethical perspective to the deployment of digital solutions. Decisions regarding automation, workforce allocation, and sustainability have far-reaching implications. By integrating operational knowledge with technological expertise, consultants can propose solutions that balance efficiency with social responsibility, ensuring that transformation is equitable, sustainable, and aligned with broader corporate values.

Operational intelligence in modern manufacturing is achieved through the convergence of data, technology, and human insight. Functional consultants play a pivotal role in synthesizing these elements. They analyze production metrics, identify inefficiencies, and configure systems that optimize workflows, improve resource utilization, and enhance quality control. Their interventions extend beyond routine troubleshooting; they redesign processes, anticipate risks, and implement proactive strategies that stabilize operations.

Consider the configuration of production orders and bills of materials. These elements are not mere technical artifacts; they are living frameworks that dictate how materials flow, how work centers are organized, and how labor is deployed. Misalignment can propagate through the supply chain, resulting in delays, waste, and diminished product quality. Consultants ensure that digital configurations mirror operational reality, translating abstract system logic into tangible improvements on the shop floor.

Lean manufacturing practices further exemplify the need for integrated expertise. Implementing lean principles through Dynamics 365 requires a comprehensive understanding of operational bottlenecks, human behavior, and workflow dependencies. Consultants guide organizations in adopting these methodologies, creating systems that reduce waste, enhance flexibility, and foster a culture of continuous improvement.

The transformation of manufacturing underscores a strategic imperative: technology and operations must operate in concert. Organizations that achieve this alignment gain the agility to respond to market shifts, the foresight to anticipate disruptions, and the capability to optimize resources across complex supply chains. Functional consultants serve as strategic partners in this endeavor, providing the expertise, vision, and operational insight necessary to embed intelligence into every facet of production.

This strategic alignment extends beyond immediate operational concerns. It shapes the culture of manufacturing enterprises, promoting collaboration, accountability, and innovation. By bridging technology and human workflows, consultants cultivate an environment in which decisions are informed, processes are resilient, and outcomes are sustainable. They transform manufacturing from a reactive, mechanistic activity into a proactive, adaptive system that thrives amid uncertainty.

As manufacturing continues to evolve, the demands placed on professionals will intensify. Emerging technologies such as predictive analytics, artificial intelligence, digital twins, and advanced automation are redefining the boundaries of possibility. Organizations require consultants who not only configure systems effectively but also anticipate future challenges, translate data into actionable insights, and cultivate operational resilience.

The Microsoft Dynamics 365 Supply Chain Management platform exemplifies this evolution, offering comprehensive capabilities for finance, operations, and manufacturing management. Professionals who master these tools are uniquely positioned to drive transformation, enabling organizations to operate with intelligence, precision, and foresight. Their role extends from configuring ERP modules to influencing enterprise strategy, integrating technical expertise with operational acumen to shape the future of manufacturing.

In this context, certification and structured mastery become crucial. Professionals who pursue rigorous validation of their skills acquire not only technical proficiency but also strategic judgment, ethical awareness, and the ability to navigate complex industrial ecosystems. These competencies are indispensable for organizations seeking to achieve sustainable growth, operational excellence, and resilience in an increasingly dynamic global market.

The contemporary manufacturing environment is defined by rapid technological advancement, globalized supply networks, and heightened consumer expectations. Within this intricate ecosystem, the role of the manufacturing functional consultant has evolved beyond technical proficiency. These professionals are strategic enablers, orchestrating workflows, guiding decision-making, and embedding intelligence into every operational layer. Their influence stretches from the granular level of production orders to enterprise-wide strategic alignment, ensuring that digital transformation is not merely implemented but deeply internalized.

Manufacturing organizations face an intricate balance of efficiency, cost management, and quality control. The integration of Dynamics 365 platforms allows enterprises to harmonize finance, operations, and production management into a cohesive framework. Yet, the potential of these systems is realized only when guided by professionals capable of translating technical configurations into actionable operational strategies. Consultants act as navigators in this terrain, interpreting data streams, mapping process interdependencies, and designing workflows that are resilient and adaptive.

Their leadership extends beyond configuring software modules. Consultants anticipate challenges, mitigate risks, and provide guidance that aligns technological capabilities with strategic objectives. They translate the abstract logic of enterprise systems into concrete operational improvements, fostering environments where efficiency, innovation, and sustainability converge. In doing so, they become indispensable architects of organizational resilience, capable of steering complex systems through uncertainty and change.

One of the defining attributes of modern manufacturing consultants is their capacity to bridge strategic intent with operational execution. The translation of executive vision into actionable processes requires both technical mastery and a profound understanding of industrial dynamics. Consultants analyze production cycles, identify inefficiencies, and recommend improvements that optimize labor allocation, material utilization, and machine throughput. These interventions are not isolated; they resonate across the supply chain, influencing inventory management, procurement decisions, and delivery timelines.

The ability to connect strategy with execution relies on a dual fluency: understanding both the capabilities of enterprise systems and the nuances of physical operations. For example, configuring a bill of materials extends beyond entering data into an ERP system. It involves understanding the sequencing of operations, material dependencies, and the human workflows that drive production efficiency. Similarly, resource scheduling is not merely an algorithmic task; it requires anticipating operator availability, maintenance cycles, and potential bottlenecks. Consultants ensure that systems serve as accelerators of operational performance, rather than obstacles.

Their role in aligning strategy and execution also encompasses risk management. Manufacturing is inherently susceptible to variability in supply, demand, and equipment performance. Consultants leverage real-time analytics, predictive forecasting, and scenario modeling to anticipate disruptions and implement contingency measures. By embedding resilience into operational processes, they transform reactive systems into proactive frameworks capable of navigating volatility and uncertainty.

In an era dominated by digital interconnectivity, operational intelligence has emerged as a competitive differentiator. Manufacturing consultants harness data from interconnected systems, translating insights into actionable strategies. Predictive analytics allows organizations to anticipate equipment failures, forecast demand fluctuations, and optimize production schedules. This intelligence, however, is valuable only when interpreted within the context of operational realities.

Functional consultants integrate predictive insights with hands-on understanding of production environments. They assess the impact of suggested interventions on human workflows, machine utilization, and supply chain synchronization. This approach ensures that decisions are both data-driven and pragmatically grounded, bridging the gap between algorithmic output and actionable operational plans. Their ability to interpret signals from multiple sources—ERP systems, IoT devices, and shop floor feedback—enables manufacturers to respond with agility, precision, and foresight.

Beyond analytics, consultants design processes that transform insights into sustained improvement. Continuous monitoring, workflow refinement, and iterative adjustments create systems capable of learning from experience. They introduce mechanisms for accountability, feedback loops, and knowledge retention, ensuring that organizational intelligence evolves alongside technological innovation. By fostering an environment of operational acuity, consultants enable enterprises to achieve sustained competitive advantage.

While technological fluency is critical, the human dimension remains central to successful transformation. Manufacturing is an ecosystem of machines, data, and people, and consultants are tasked with harmonizing these elements. They design systems that accommodate human behavior, optimize ergonomic workflows, and enhance collaboration across functions. This human-centric perspective ensures that digital interventions are adopted effectively and contribute to measurable operational improvement.

Training, mentorship, and stakeholder engagement are integral to this process. Consultants guide operators through new interfaces, clarify complex workflows, and provide context for system decisions. They cultivate trust by demonstrating how technology supports human goals rather than replacing them. By bridging technical complexity and practical application, they reduce resistance, enhance adoption, and cultivate a culture of continuous improvement.

Additionally, ethical considerations are woven into their approach. Decisions regarding automation, labor allocation, and workflow redesign carry implications for employee well-being, skill development, and organizational culture. Consultants incorporate these dimensions into system configuration and process optimization, ensuring that transformation aligns with corporate values and promotes equitable outcomes. Their influence extends beyond efficiency metrics, shaping the human experience within industrial environments.

Modern manufacturing extends beyond the factory floor. Supply chain intricacies, global logistics, and supplier coordination are integral to operational success. Functional consultants play a pivotal role in integrating these components, ensuring that production, procurement, and distribution operate in harmony. Their work includes configuring inventory management systems, establishing real-time communication channels with suppliers, and optimizing transportation planning.

By leveraging Dynamics 365 platforms, consultants provide enterprises with visibility across the value chain. They monitor inventory levels, track production progress, and identify potential disruptions before they escalate. This proactive approach enables organizations to align production with demand, reduce waste, and enhance responsiveness to market fluctuations. Consultants translate complex system outputs into strategic insights that inform decision-making across procurement, production, and distribution functions.

The integration of supply chain processes also facilitates collaboration and alignment. Consultants enable cross-functional teams to work cohesively, ensuring that production schedules reflect supplier constraints and customer requirements. By connecting data, people, and processes, they create operational coherence that strengthens resilience, enhances efficiency, and supports long-term strategic objectives.

Lean manufacturing principles have become essential for competitive performance. Functional consultants apply these principles through ERP configurations, process mapping, and workflow redesign. Their expertise ensures that lean methodologies are not theoretical but embedded into daily operations. They analyze value streams, identify bottlenecks, and implement continuous improvement initiatives that reduce waste and increase throughput.

The consultant’s role in process optimization encompasses both macro and micro perspectives. At the macro level, they assess enterprise-wide workflows, ensuring alignment between finance, operations, and production management. At the micro level, they scrutinize individual processes, machine setups, and human interactions, identifying opportunities for refinement. This dual lens ensures that efficiency gains are sustainable, scalable, and integrated with broader organizational objectives.

Process optimization is also informed by predictive analytics. Consultants utilize historical data and real-time monitoring to anticipate constraints, simulate alternative workflows, and implement evidence-based interventions. By combining lean principles with advanced analytics, they create adaptive systems that respond dynamically to operational fluctuations and strategic priorities.

Sustainability and ethical considerations are increasingly central to manufacturing strategy. Functional consultants integrate these dimensions into system configuration and process design. They assess the environmental impact of workflows, optimize resource consumption, and design labor practices that promote fairness and inclusivity. Technology is leveraged not only for efficiency but also for responsible stewardship of resources and human capital.

Automation, while enhancing productivity, requires careful ethical consideration. Consultants evaluate the implications for workforce dynamics, skill development, and job satisfaction. They balance the benefits of automation with the need to maintain meaningful employment, creating systems that enhance human capability rather than diminish it. This ethical framework ensures that transformation is not only technically effective but also socially responsible.

Sustainable practices extend to supply chain management as well. Consultants implement configurations that minimize waste, optimize transportation efficiency, and align production with environmentally conscious objectives. By embedding these principles into enterprise systems, they enable organizations to achieve operational excellence while upholding sustainability commitments.

The influence of a manufacturing functional consultant is strategic, operational, and cultural. Beyond configuring systems and optimizing processes, they act as change agents. They guide organizations through transformation, align stakeholders around common objectives, and foster a culture of innovation and continuous improvement. Their work ensures that technology adoption translates into tangible performance gains and enduring organizational resilience.

Change management is central to their impact. Consultants design adoption strategies, conduct training, and facilitate workshops that enable employees to embrace new workflows. They anticipate resistance, address concerns, and demonstrate the practical benefits of digital transformation. This approach ensures that investments in technology yield measurable returns and that transformation is embraced across all levels of the organization.

Consultants also serve as mentors, sharing knowledge, cultivating talent, and fostering cross-functional collaboration. By transferring expertise and building organizational capacity, they leave a lasting imprint on the enterprise, ensuring that transformation extends beyond immediate projects and becomes embedded in the corporate DNA.

As manufacturing continues to evolve, the demand for professionals who can integrate technology, operations, and human considerations will intensify. Emerging trends such as artificial intelligence, predictive maintenance, digital twins, and advanced automation require consultants to remain agile, continually expanding their expertise and adapting to new paradigms. Their role is not static; it is a continual journey of learning, refinement, and strategic impact.

Dynamic platforms like Microsoft Dynamics 365 empower consultants to orchestrate complex workflows, synchronize supply chains, and optimize resource allocation. Mastery of these tools allows professionals to influence enterprise strategy, anticipate operational challenges, and embed intelligence into every facet of production. Their work ensures that digital transformation is not a superficial exercise but a strategic evolution that enhances efficiency, sustainability, and human experience.

By embracing lifelong learning, consultants position themselves at the forefront of industrial innovation. They cultivate technical acumen, operational insight, and strategic judgment, enabling organizations to navigate complexity and uncertainty with confidence. Their expertise extends beyond immediate outcomes, shaping long-term resilience, innovation, and competitive advantage.

Achieving proficiency in modern manufacturing requires more than familiarity with machines or software; it demands the integration of strategic insight, operational understanding, and technological fluency. The journey to becoming a certified manufacturing functional consultant within the Dynamics 365 ecosystem is rigorous yet transformative, cultivating a professional who can navigate the complexities of supply chains, production workflows, and enterprise decision-making. The process involves intensive exploration of both finance and operational domains, ensuring that consultants comprehend the interdependencies of organizational functions while mastering tools that drive efficiency and resilience.

Candidates entering this path confront the dual challenge of technical mastery and contextual application. They must internalize the architecture of enterprise systems, understand the flow of data across multiple modules, and appreciate the subtleties of production environments. The certification journey transforms individuals from system users into orchestrators of change, equipping them with the foresight to anticipate bottlenecks, align stakeholders, and design workflows that harmonize technology with human endeavor.

At the core of the certification experience lies the imperative to understand enterprise operations holistically. Candidates begin by exploring the intricate web of processes that underpin finance, procurement, inventory management, and production control. This exploration reveals how decisions in one area ripple across the organization. For instance, a delay in material acquisition can disrupt production schedules, compromise quality, and increase costs, highlighting the need for precise orchestration.

Consultants learn to configure systems to reflect operational goals, ensuring that digital workflows mirror the realities of manufacturing floors. They examine transaction flows, chart interdepartmental dependencies, and explore the mechanisms that enable visibility across functions. This understanding is not purely academic; it is framed within real-world scenarios that challenge candidates to synthesize information, anticipate consequences, and optimize outcomes. The objective is to cultivate a mindset that merges technical acumen with operational prudence.

A critical aspect of certification involves mastering production workflows, including discrete and process manufacturing operations. Candidates gain insight into the lifecycle of production orders, resource allocation, and capacity planning. They explore how bills of materials function as living structures, adapting to changes in design, supply, and demand. Understanding these elements allows consultants to implement systems that optimize throughput, reduce waste, and accommodate human and machine limitations.

The training emphasizes the importance of lean principles in manufacturing. Candidates analyze workflows to identify inefficiencies, unnecessary steps, or potential bottlenecks, and configure systems that support continuous improvement. By embedding these principles into enterprise software, consultants ensure that processes are both agile and sustainable. This approach fosters an environment where operational decisions are informed by data, guided by strategy, and aligned with organizational values.

Modern manufacturing demands more than automated operations; it requires intelligence that integrates human factors with digital systems. Certification candidates study shop floor control, exploring how system configuration affects operator behavior, machine utilization, and overall productivity. They learn to design dashboards, workspaces, and reporting structures that provide clarity, minimize confusion, and support real-time decision-making.

Human-centric design principles are woven throughout the training. Candidates consider ergonomics, cognitive load, and workflow intuitiveness, ensuring that systems enhance rather than hinder human performance. They recognize that even the most sophisticated technology can falter if it does not accommodate human behavior. By combining technical rigor with an understanding of human workflows, consultants create operational environments that are efficient, safe, and adaptable.

As automation and digital systems become central to manufacturing, ethical considerations gain prominence. Certification emphasizes the impact of system configurations on workforce dynamics, job satisfaction, and equitable labor practices. Candidates explore scenarios in which technology influences employment patterns, productivity expectations, and environmental sustainability. They are trained to balance efficiency gains with ethical stewardship, ensuring that digital transformation serves both organizational goals and societal responsibilities.

Consultants also consider sustainability in supply chain and production planning. They assess resource utilization, waste reduction strategies, and energy consumption patterns. Systems are configured not merely for operational efficiency but to align with broader environmental objectives, demonstrating that technology can advance both economic and ecological imperatives.

A defining feature of the certification process is the emphasis on scenario-based learning. Candidates engage with realistic case studies that replicate the complexities of modern manufacturing environments. These exercises require them to navigate supply chain disruptions, equipment failures, and demand fluctuations while maintaining operational efficiency. Each scenario challenges them to apply analytical thinking, problem-solving skills, and digital expertise simultaneously.

Through these exercises, consultants internalize the interconnectedness of enterprise functions. They observe how decisions in production affect inventory, finance, and customer satisfaction. They explore the consequences of configuration choices, understanding that each setting in the system carries operational, financial, and human implications. This applied learning transforms theoretical knowledge into actionable insight, preparing candidates to lead transformation initiatives in real-world settings.

Modern manufacturing relies heavily on predictive analytics to anticipate trends, optimize scheduling, and mitigate risk. Certification candidates explore tools that harness historical and real-time data to support strategic decision-making. They learn to interpret predictive outputs, align them with production goals, and configure systems to respond dynamically to changing conditions.

Consultants are trained to balance algorithmic recommendations with operational reality. Predictive insights must be tempered with human judgment, resource availability, and shop floor constraints. By integrating analytics into daily operations, consultants enable proactive management, reducing downtime, improving resource allocation, and enhancing overall production agility.

The certification process emphasizes not only initial competence but also the ability to foster continuous improvement. Candidates learn strategies to monitor performance metrics, identify emerging inefficiencies, and refine workflows iteratively. They develop frameworks for knowledge transfer, training, and mentoring, ensuring that operational excellence is perpetuated across teams and future projects.

By cultivating a mindset of continuous learning, consultants prepare organizations to adapt to evolving technological landscapes. They encourage experimentation within controlled parameters, enabling enterprises to innovate without jeopardizing operational stability. This culture of iterative refinement ensures that digital transformation is sustainable, scalable, and resilient.

Certification cultivates professionals who are fluent in both technical systems and strategic imperatives. Consultants acquire mastery of Dynamics 365 functionalities, including finance, operations, production control, and supply chain integration. Simultaneously, they develop the capacity to translate system capabilities into strategic advantage, aligning technology deployment with business objectives and long-term goals.

This dual expertise positions consultants as strategic partners rather than mere implementers. They guide executives in decision-making, advise operations managers on workflow optimization, and collaborate with IT teams to ensure seamless integration. Their influence extends across hierarchical boundaries, shaping organizational outcomes and fostering alignment between technological capabilities and business strategy.

Certification examinations represent a culmination of rigorous preparation, practical application, and critical thinking. The exams challenge candidates to demonstrate not only technical knowledge but also operational understanding, analytical reasoning, and ethical judgment. They test the ability to configure systems in alignment with production goals, anticipate challenges, and integrate human factors into operational design.

The testing process reinforces holistic learning. Candidates encounter questions that simulate real-world challenges, requiring them to navigate complex scenarios, prioritize actions, and justify decisions. Success signifies more than proficiency; it reflects readiness to assume responsibility for enterprise-level transformation, to guide teams through change, and to embed intelligence into every operational layer.

Beyond technical configuration, certified consultants assume the role of mentors within their organizations. They share expertise, develop training programs, and cultivate a culture of digital literacy and operational awareness. Their guidance accelerates adoption, enhances skill development, and reinforces best practices. By embedding knowledge into the organization, they amplify the long-term impact of digital transformation initiatives.

Consultants influence organizational culture by modeling ethical and sustainable practices. They demonstrate how technology can enhance productivity while respecting human workflows and environmental constraints. This influence extends to decision-making, project planning, and strategic prioritization, reinforcing a culture of accountability, collaboration, and continuous improvement.

Manufacturing environments are inherently complex, with interdependent systems, fluctuating demand, and variable human performance. Certification prepares consultants to navigate this complexity with prudence and foresight. They develop the ability to anticipate cascading effects, manage operational trade-offs, and implement interventions that optimize outcomes without compromising safety, quality, or workforce morale.

The capacity to manage complexity is enhanced through scenario analysis, predictive modeling, and immersive problem-solving exercises. Consultants learn to synthesize data, evaluate alternatives, and select solutions that balance efficiency, sustainability, and ethical responsibility. This skill set ensures that transformation initiatives are not only successful but resilient to unforeseen challenges.

Certified consultants extend their influence beyond immediate operational improvements. They shape organizational strategy, optimize supply chain performance, and embed intelligence into decision-making processes. Their work enhances responsiveness, reduces waste, and elevates overall operational excellence. By integrating technology, human factors, and strategic insight, they transform manufacturing into a proactive, adaptive, and resilient enterprise.

The ripple effects of certification extend to leadership development, talent retention, and organizational culture. Certified consultants inspire confidence, foster collaboration, and guide enterprises toward sustainable growth. Their expertise ensures that investments in technology translate into tangible benefits, reinforcing the value of digital transformation across multiple dimensions.

Integrating Systems and Operational Strategy

In the contemporary landscape of manufacturing, the orchestration of digital systems and operational strategy is no longer optional but essential. The certified manufacturing functional consultant within Dynamics 365 embodies this convergence, serving as both an interpreter and architect of operational intelligence. Their work begins with the meticulous alignment of enterprise software capabilities to production realities, ensuring that workflows, data flows, and system logic mirror the complex rhythms of factory operations. By embedding intelligence into supply chains and production scheduling, they create environments where decision-making is agile, predictive, and deeply informed by data.

This integration extends beyond the mere implementation of software. Consultants must analyze interdependencies between finance, procurement, inventory, and production modules, understanding how variations in one area cascade across others. They design systems that not only track material flows but anticipate demand fluctuations, adapt to resource constraints, and optimize capacity utilization. The end goal is an operational ecosystem where efficiency, precision, and resilience coalesce, providing both tactical clarity and strategic foresight.

The modern consultant leverages predictive analytics and real-time data streams to transform raw information into actionable insights. They configure dashboards and workspaces that present operators and managers with clear, comprehensible intelligence, facilitating rapid responses to production anomalies or supply chain disruptions. Predictive models are calibrated to reflect historical patterns, current resource availability, and anticipated market conditions, creating a digital foresight mechanism that guides decisions from the shop floor to the executive suite.

Beyond technical acumen, consultants cultivate the ability to contextualize analytics within operational realities. Predictive alerts must align with human capabilities and procedural constraints; algorithms are valuable only when interpreted and applied thoughtfully. By bridging the gap between machine-generated insights and human judgment, consultants ensure that technology serves as an enabler rather than a replacement, empowering staff to act decisively and confidently.

A critical aspect of consulting success lies in fostering adoption and guiding organizations through change. Certified professionals recognize that even the most robust system configurations are ineffective if they are not embraced by the workforce. They lead workshops, train supervisors, and collaborate closely with production teams to translate complex configurations into practical routines. Their communication is clear, empathetic, and anticipatory, addressing skepticism and building trust among operators who may have experienced failed system rollouts in the past.

Human-centric implementation emphasizes not only efficiency but the experience of those interacting with systems daily. Consultants consider ergonomics, cognitive load, and procedural clarity, designing workflows that reduce errors, streamline operations, and maintain morale. They understand that adoption is a social as well as technical process, requiring alignment of incentives, reinforcement of training, and continuous feedback loops. By harmonizing technology with human behavior, they ensure that operational transformation is both sustainable and resilient.

Manufacturing today depends on interconnected supply networks and responsive production systems. Consultants configure Dynamics 365 to synchronize procurement, inventory, and production in real-time, creating visibility across the value chain. This capability allows for proactive risk management, timely mitigation of disruptions, and optimized allocation of resources. The consultant’s insight into system behavior enables predictive replenishment, dynamic scheduling, and adaptive planning, which together enhance operational resilience and reduce waste.

Through these strategies, consultants ensure that supply chain decisions are informed, deliberate, and strategically aligned. They analyze vendor performance, transportation logistics, and inventory policies to maintain a delicate equilibrium between cost, efficiency, and service levels. By embedding intelligence into these processes, they transform reactive operations into anticipatory systems capable of absorbing shocks and sustaining output under uncertainty.

In addition to system configuration and analytics, certified consultants champion process optimization. They apply lean principles to eliminate inefficiencies, reduce cycle times, and enhance throughput. By mapping workflows, identifying redundancies, and streamlining task sequences, they design production processes that maximize value while minimizing waste. This approach fosters continuous improvement, ensuring that operational enhancements are enduring rather than temporary.

Consultants leverage their understanding of production constraints to adapt processes to the realities of human performance and machine limitations. They analyze bottlenecks, implement standardized procedures, and create responsive scheduling models that adjust to unforeseen disruptions. The combination of technical systems expertise and process insight allows them to create manufacturing environments that are both disciplined and flexible, capable of sustaining high performance in dynamic contexts.

Modern manufacturing carries ethical responsibilities that extend beyond compliance and profit. Certified consultants consider the implications of automation on labor, the environmental impact of production practices, and the social responsibilities of organizational decisions. They configure systems to promote equitable labor allocation, optimize resource consumption, and facilitate sustainable operations. This perspective ensures that digital transformation serves broader organizational and societal goals, embedding stewardship into operational design.

By integrating sustainability metrics, resource optimization strategies, and ethical workflow practices into system configurations, consultants guide enterprises toward operations that are economically efficient, environmentally responsible, and socially conscious. They understand that long-term competitiveness relies not only on technology but on trust, responsibility, and the judicious balance of human, material, and digital resources.

Certified consultants often assume leadership roles in technology-driven environments, shaping the direction of transformation initiatives. They mentor colleagues, influence strategic decisions, and bridge the gap between operational teams and executive management. Their insight enables organizations to prioritize initiatives, allocate resources effectively, and maintain alignment between digital investments and business objectives. By fostering a culture of collaboration, transparency, and learning, they magnify the impact of technological deployment and create conditions for sustainable innovation.

Leadership also involves modeling best practices in problem-solving and decision-making. Consultants demonstrate how to use system data to make informed choices, anticipate operational risks, and respond adaptively to disruptions. They cultivate analytical thinking and a proactive mindset across teams, instilling confidence and capability in both technical and non-technical personnel.

The certification journey emphasizes scenario-based learning, immersing candidates in realistic manufacturing challenges. Exercises simulate supply chain interruptions, production variability, and system failures, requiring consultants to apply knowledge under pressure. These experiences cultivate adaptability, critical thinking, and operational intuition. Candidates learn to identify root causes, prioritize interventions, and implement solutions that balance efficiency, safety, and human considerations.

Real-world application reinforces the integration of systems and human-centric strategies. Consultants experiment with predictive maintenance, dynamic scheduling, and resource optimization in controlled scenarios, internalizing best practices before encountering similar complexities in actual manufacturing environments. This experiential learning cultivates confidence, judgment, and resilience—qualities essential for effective enterprise transformation.

A hallmark of successful consultancy is the ability to disseminate knowledge across the organization. Certified professionals design training programs, create reference materials, and mentor team members to build institutional competence. By transferring expertise in system configuration, operational best practices, and process improvement, they ensure that transformation initiatives are not dependent on a single individual but embedded within the organizational culture.

Mentoring also extends to leadership development. Consultants guide emerging managers in interpreting system data, managing workflows, and balancing operational and strategic priorities. Through this influence, they cultivate a cadre of informed decision-makers capable of sustaining digital transformation efforts over the long term.

The consultant’s work revolves around configuration excellence—designing system parameters that accurately reflect production requirements, operational goals, and strategic objectives. They adjust workflows, schedule resources, and manage user access to align digital functionality with organizational intent. This alignment ensures that operational decisions are supported by accurate, timely, and actionable information, enhancing both efficiency and decision-making quality.

Strategic alignment requires understanding the interplay between enterprise systems, production realities, and business objectives. Consultants assess how configuration choices impact cost, throughput, quality, and compliance, making adjustments to maintain optimal performance. They also anticipate future needs, building flexibility into system designs that accommodate growth, market shifts, and technological evolution.

Digital transformation in manufacturing is as much about people as it is about technology. Certified consultants act as facilitators, guiding organizations through change with empathy and insight. They recognize the cultural dimensions of technology adoption, addressing resistance, fostering trust, and reinforcing alignment with organizational values. Their role extends beyond technical instruction to shaping attitudes, behaviors, and expectations, ensuring that transformation initiatives are embraced rather than resisted.

Cultural integration involves ongoing engagement with teams, clear communication of objectives, and visible demonstration of benefits. Consultants monitor adoption rates, solicit feedback, and adapt training approaches to meet emerging needs. This iterative process strengthens the connection between system capability and human utilization, producing measurable improvements in performance and engagement.

In dynamic manufacturing environments, operational foresight is crucial. Certified consultants anticipate potential disruptions, model contingencies, and implement safeguards to maintain continuity. They use predictive insights, scenario planning, and system simulations to identify vulnerabilities and design mitigation strategies. This proactive approach reduces downtime, prevents costly errors, and enhances organizational resilience.

Risk management also encompasses ethical and environmental considerations. Consultants assess the impact of decisions on workforce equity, regulatory compliance, and sustainability outcomes. By embedding foresight and prudence into system design and operational planning, they enable organizations to navigate uncertainty with confidence and integrity.

The philosophy of continuous improvement underpins all aspects of certified consultancy. Consultants configure systems to capture performance metrics, track key indicators, and enable iterative enhancements. They identify areas for optimization, implement corrective measures, and monitor outcomes to ensure sustained gains. By institutionalizing feedback loops and performance monitoring, they create a self-reinforcing cycle of refinement and excellence.

Continuous improvement extends beyond process efficiency to include human performance, system utilization, and strategic alignment. Consultants foster a culture of inquiry, encouraging teams to question assumptions, explore alternatives, and pursue operational innovation. This mindset ensures that manufacturing operations remain adaptive, responsive, and forward-looking.

In today’s manufacturing landscape, certified professionals are increasingly recognized not merely for their technical proficiency but for their capacity to lead transformative initiatives. The Dynamics 365 manufacturing functional consultant operates at the confluence of technology, process insight, and human intuition, positioning them as strategic architects within enterprises. Their influence extends beyond configuration and deployment to shaping operational philosophies, optimizing workflows, and embedding resilience across production ecosystems. By aligning system capabilities with organizational objectives, they cultivate environments where efficiency, innovation, and ethical foresight converge.

Leadership in this context is multifaceted. It requires guiding cross-functional teams, mentoring emerging talent, and translating technical potential into operational reality. Certified consultants act as navigators of complexity, anticipating challenges before they materialize and devising strategies that balance immediate operational demands with long-term organizational growth. This capacity to orchestrate both human and digital assets distinguishes them as indispensable contributors to enterprise success.

A hallmark of advanced consultancy is the ability to conduct sophisticated scenario modeling. Professionals use Dynamics 365 to simulate supply chain fluctuations, production delays, and resource constraints, enabling proactive decision-making. By integrating predictive analytics with historical performance data, they identify vulnerabilities, optimize throughput, and recommend interventions that enhance both agility and stability. These simulations are not abstract exercises; they replicate the intricate interdependencies of real-world manufacturing, fostering a foresight that mitigates risk while maximizing opportunity.

Strategic planning extends to resource allocation, inventory management, and workforce deployment. Consultants analyze trade-offs between cost, quality, and speed, designing strategies that harmonize operational efficiency with business imperatives. This foresight ensures that enterprises can navigate uncertainty without sacrificing productivity or ethical standards, creating a competitive advantage in markets that are increasingly volatile and interconnected.

The certified consultant is also an agent of innovation, leveraging digital dexterity to introduce new methodologies and technologies into traditional manufacturing contexts. They explore the application of AI, machine learning, and IoT-enabled sensors to optimize processes, predict maintenance needs, and enhance product quality. By interpreting these technologies through the lens of operational reality, they ensure that innovation is both practical and impactful, enhancing output while respecting human and environmental considerations.

Innovation is cultivated not in isolation but through iterative experimentation and collaborative problem-solving. Consultants guide teams in piloting new workflows, analyzing outcomes, and refining configurations to achieve maximum efficacy. Their capacity to translate emerging technological potential into tangible operational improvements positions them as both thought leaders and pragmatic implementers.

Modern manufacturing increasingly demands ethical stewardship, and certified consultants play a central role in this evolution. They consider the implications of automation on workforce dynamics, the environmental footprint of production processes, and the social responsibilities inherent in operational decisions. By configuring systems to optimize resource use, reduce waste, and facilitate equitable labor practices, they embed sustainability into the operational fabric of the enterprise.

This ethical orientation extends to long-term planning and strategic foresight. Consultants anticipate how regulatory shifts, environmental imperatives, and societal expectations will influence production, designing systems that are resilient, adaptive, and aligned with sustainable principles. Their work ensures that digital transformation is not only efficient but responsible, enhancing corporate reputation while safeguarding operational integrity.

Effective consultancy in manufacturing requires fostering cross-functional collaboration. Certified professionals act as intermediaries between IT teams, operations managers, finance departments, and executive leadership. They translate complex technical configurations into actionable insights, ensuring that all stakeholders comprehend the implications of system changes. This ability to communicate fluently across diverse domains enhances decision-making, reduces misalignment, and accelerates the adoption of innovative solutions.

Collaboration also involves cultivating shared ownership of transformation initiatives. Consultants guide teams in setting realistic objectives, establishing clear accountability, and monitoring progress. By facilitating dialogue and encouraging iterative feedback, they create an organizational culture where continuous improvement is ingrained, and digital tools are leveraged to their fullest potential.

Certified consultants harness advanced analytics to uncover insights that drive operational excellence. By analyzing production metrics, supply chain data, and financial performance indicators, they identify trends, anticipate disruptions, and recommend strategic interventions. These insights are translated into configurations within Dynamics 365, enabling real-time adjustments and predictive decision-making that enhance productivity and reduce costs.

Analytics also serve as a foundation for continuous learning within the organization. Consultants design dashboards and reporting structures that provide stakeholders with clear visibility into key performance indicators. This transparency empowers teams to act decisively, fostering accountability and enabling a culture where data-driven decision-making becomes second nature.

A defining characteristic of expert consultants is their commitment to mentorship and knowledge dissemination. They train operational staff, guide junior consultants, and develop learning resources that cultivate organizational competence. By sharing expertise in system configuration, process optimization, and strategic planning, they ensure that transformation efforts are scalable, sustainable, and deeply embedded within corporate culture.

Mentorship also reinforces ethical and operational standards. Consultants model best practices, demonstrate critical thinking in decision-making, and cultivate adaptive problem-solving skills among teams. This investment in human capital amplifies the impact of technological transformation, creating a workforce capable of sustaining innovation and resilience long after initial implementation.

Deploying Dynamics 365 across manufacturing operations involves navigating intricate interdependencies. Certified consultants manage these complexities by orchestrating workflows, aligning system modules, and configuring processes to accommodate production realities. They balance multiple priorities, including scheduling, inventory management, and quality control, ensuring that deployments enhance operational performance without causing disruption.

This orchestration requires both technical expertise and strategic vision. Consultants anticipate challenges, design contingency plans, and coordinate stakeholders to achieve seamless integration. By maintaining focus on both immediate operational requirements and long-term enterprise objectives, they create systems that are robust, adaptive, and aligned with organizational priorities.

Certified consultants ensure that technology deployment reflects broader organizational vision. They connect system configurations with strategic objectives, operational goals, and cultural values, creating a cohesive approach to transformation. This alignment enhances decision-making, strengthens accountability, and ensures that digital tools support rather than dictate enterprise direction.

Consultants also evaluate how changes in technology impact human behavior and organizational culture. They design interventions that respect existing workflows while promoting innovation, fostering a balance between continuity and transformation. This holistic approach ensures that digital evolution enhances rather than disrupts the enterprise ecosystem.

In fast-paced manufacturing environments, resilience is a key determinant of success. Certified consultants design processes that can withstand disruptions, adapt to changing market conditions, and maintain operational continuity. They implement dynamic scheduling, predictive maintenance, and flexible resource allocation, ensuring that production remains efficient and responsive even under stress.

Adaptability is cultivated through continuous monitoring, scenario testing, and process refinement. Consultants anticipate potential failures, design mitigation strategies, and create feedback loops that allow for real-time adjustment. This proactive stance transforms manufacturing from a reactive system to a resilient, forward-looking ecosystem capable of thriving amidst uncertainty.

Beyond operational execution, certified consultants cultivate strategic foresight. They anticipate industry trends, regulatory shifts, and technological innovations, integrating these insights into planning and system design. This anticipatory approach allows enterprises to pivot quickly, seize emerging opportunities, and mitigate risks before they escalate.

Strategic foresight also involves evaluating the long-term impact of operational decisions. Consultants consider financial performance, sustainability outcomes, workforce implications, and organizational culture in their planning. By embedding foresight into every level of decision-making, they position organizations to achieve sustainable growth and maintain competitive advantage.

The integration of real-time analytics, predictive modeling, and operational insight enhances decision-making agility. Certified consultants configure Dynamics 365 to provide timely, actionable information to stakeholders at all levels. This capability reduces latency in response, empowers teams to act decisively, and ensures that operational adjustments are informed by accurate, comprehensive data.

Agility is further reinforced through scenario planning and workflow simulation. Consultants guide teams in evaluating potential courses of action, assessing risks, and selecting optimal strategies. This iterative approach fosters confidence, reduces errors, and aligns operational execution with strategic objectives.

Certified consultants instill a culture of continuous improvement within manufacturing organizations. They design systems to capture performance data, track metrics, and identify areas for optimization. By promoting iterative enhancement, they ensure that operations evolve in response to emerging challenges, technological advancements, and shifting market demands.

Continuous improvement also emphasizes human performance. Consultants monitor operator interaction with systems, provide ongoing training, and encourage feedback-driven refinement. This holistic perspective ensures that both technology and people develop in tandem, sustaining operational excellence and organizational adaptability.

A defining strength of certified consultants is their ability to bridge the gap between technological capability and human experience. They design systems that enhance productivity while respecting human workflow, cognitive load, and ergonomics. By aligning machine logic with operator behavior, they create environments where technology empowers rather than hinders human performance.

This bridge extends to stakeholder communication. Consultants translate complex technical insights into understandable guidance, enabling executives, managers, and operators to make informed decisions. Their ability to navigate both digital and human domains ensures that transformation initiatives are comprehensible, actionable, and widely adopted.

The work of certified consultants leaves a lasting legacy. By embedding operational intelligence, fostering ethical practices, and cultivating organizational capability, they influence enterprise trajectory beyond immediate projects. Their strategic guidance shapes processes, decision-making frameworks, and organizational culture, ensuring that transformation initiatives endure and evolve over time.

Influence extends to mentorship, collaboration, and knowledge transfer. Consultants create a ripple effect, empowering teams, enhancing skill sets, and fostering a culture of innovation. This broad impact reinforces the consultant’s role as a strategic co-creator, shaping both immediate operational outcomes and long-term organizational resilience.

The journey of becoming a certified Microsoft Dynamics 365 Supply Chain Management, Manufacturing Functional Consultant is more than an accumulation of technical knowledge or completion of exams; it is a transformative endeavor that reshapes the way professionals perceive, engage with, and influence the manufacturing ecosystem. In an era where factories are increasingly intelligent, supply chains are interconnected, and operational decisions are driven by real-time data, these professionals emerge as strategic architects who bridge the gap between technology and human experience. They do not simply implement systems; they embed intelligence, resilience, and ethical considerations into every layer of production, ensuring that digital transformation aligns with organizational objectives, operational realities, and societal responsibilities.

Through rigorous training and certification, consultants develop a profound understanding of how finance, operations, and manufacturing processes interconnect, enabling them to anticipate challenges, optimize workflows, and guide enterprises toward sustainable, high-performance outcomes. Their expertise allows them to model scenarios, manage risks, and configure systems in a way that balances efficiency, quality, and human factors, transforming theoretical knowledge into practical, real-world solutions. This combination of technical mastery, operational insight, and strategic foresight elevates them from system implementers to orchestrators of enterprise evolution, capable of shaping processes that endure and adapt in dynamic markets.

Certified professionals also play a critical role in fostering collaboration, knowledge sharing, and continuous improvement within organizations. By mentoring teams, translating complex technical concepts into actionable guidance, and encouraging iterative refinement, they create cultures where innovation thrives and operational excellence is sustained. They consider not only the immediate impact of technology on production but also long-term implications for workforce dynamics, environmental sustainability, and organizational culture, ensuring that transformation initiatives are both effective and responsible.

The certification journey instills a mindset of lifelong learning and adaptive thinking, equipping professionals to navigate the accelerating pace of technological advancements such as artificial intelligence, predictive maintenance, digital twins, and automation. They remain relevant by expanding expertise, engaging with broader professional communities, and continuously translating knowledge into impactful, ethical, and strategic action. Their influence extends beyond operational optimization to shaping enterprise vision, aligning stakeholder objectives, and driving change that reflects both efficiency and human-centric values.

Ultimately, the role of the certified Dynamics 365 Manufacturing Functional Consultant embodies a new archetype of professional leadership—one that harmonizes technical capability with strategic insight, operational dexterity with ethical stewardship, and human empathy with digital intelligence. They become custodians of transformation, shaping not only the processes and systems of today but also the resilient, intelligent, and responsible manufacturing environments of the future. Through their work, organizations gain more than optimized operations; they gain visionary partners who translate complexity into clarity, uncertainty into opportunity, and technology into purposeful action, leaving a lasting legacy of innovation, efficiency, and sustainable progress across the manufacturing landscape.

Study with ExamSnap to prepare for Microsoft Certified: Dynamics 365 Supply Chain Management Manufacturing Functional Consultant Associate Practice Test Questions and Answers, Study Guide, and a comprehensive Video Training Course. Powered by the popular VCE format, Microsoft Certified: Dynamics 365 Supply Chain Management Manufacturing Functional Consultant Associate Certification Exam Dumps compiled by the industry experts to make sure that you get verified answers. Our Product team ensures that our exams provide Microsoft Certified: Dynamics 365 Supply Chain Management Manufacturing Functional Consultant Associate Practice Test Questions & Exam Dumps that are up-to-date.

Microsoft Training Courses

SPECIAL OFFER: GET 10% OFF

This is ONE TIME OFFER

A confirmation link will be sent to this email address to verify your login. *We value your privacy. We will not rent or sell your email address.

Download Free Demo of VCE Exam Simulator

Experience Avanset VCE Exam Simulator for yourself.

Simply submit your e-mail address below to get started with our interactive software demo of your free trial.